A Major Renovation of an Historic UW Building Retains the Character of the Campus Quad While Improving Access and Sustainability

Savery Hall Renovation

Hoffman performed a complete “makeover” for one of the four buildings that makes up the university’s historic “quad.” One wing of the building was built in 1920, one in 1917, and Hoffman updated the whole structure with modern systems, ADA access, and an additional lecture hall, all in the heart of a busy campus.

The restoration enlarged the 102,000 SF, four-story building to 104,000 SF. In addition to a modern electrical system, Hoffman added a second lecture hall with at-grade access for both halls, and additional accessibility features to comply with the ADA. Hoffman has brought the building up to modern standards while retaining its historic look and feel.

Challenge

Sustainable design was a key project goal, but Savery Hall’s historical significance prevented the addition of any external sunshades over the south side of the building, which would normally reduce heat gain.

Solution

An efficient building envelope, lower lighting power densities, and energy-efficient HVAC design all combine to achieve a potential carbon emissions reduction of 25-30% over standard code requirements. The HVAC solution was to install a mixed-mode system utilizing natural ventilation and variable refrigerant flow. Natural ventilation through the use of operable windows and built-in “wind towers” creates a warm air buoyancy to induce air flow.

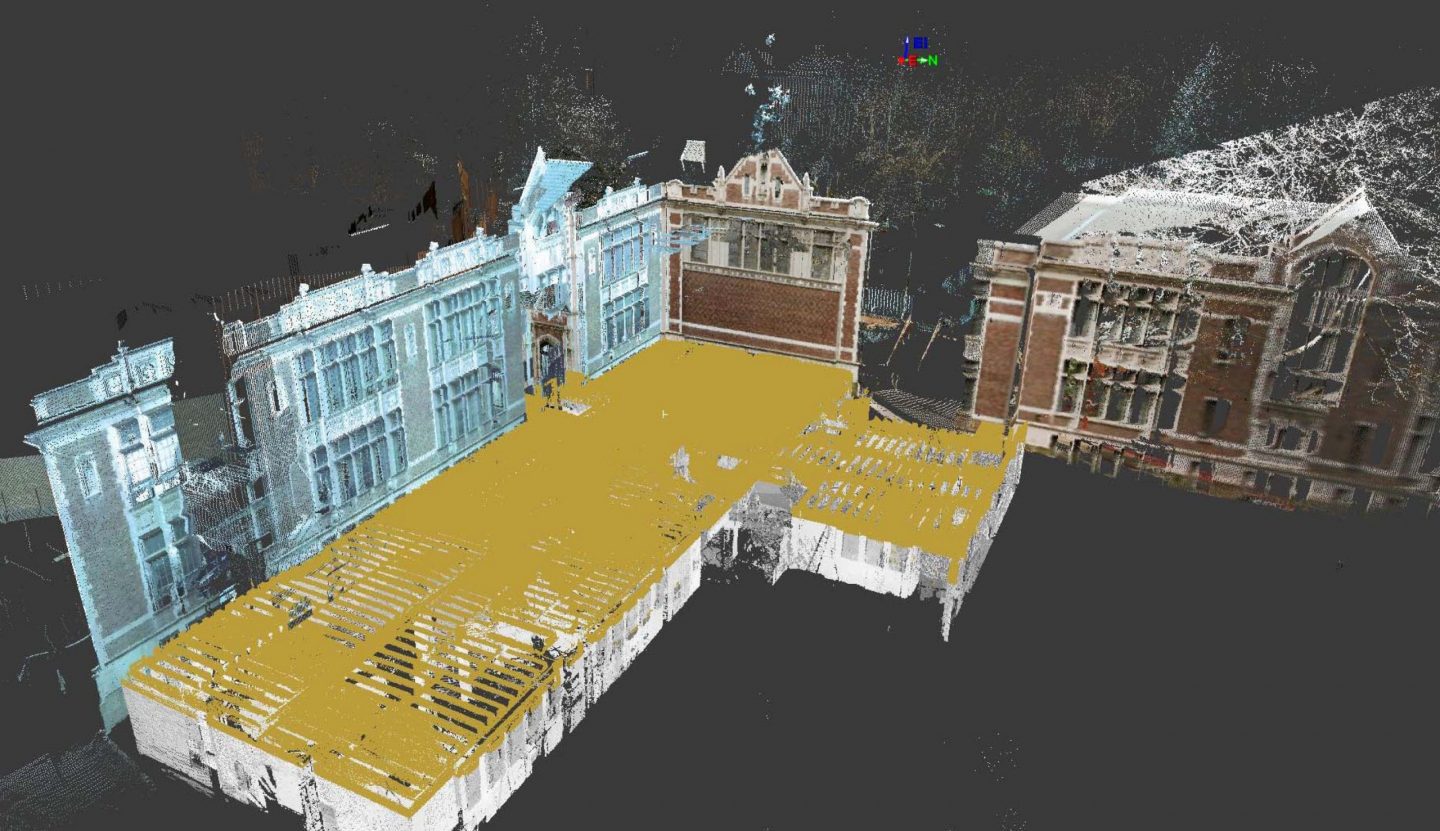

Laser Scanning for Accurate As-Built Information

We have had great success on historic buildings that required intense coordination with existing structures. At the Savery Hall renovation, 3D laser scanning enabled Hoffman and the designer to incorporate this 3D information into our BIM and create highly accurate as-built CAD structural frame drawings.

One wing of the building was built in 1917, the other in 1920, and Hoffman brought the venerable structure up to date with new classroom and lecture facilities throughout. Initial surveys revealed that the as-built structure differed significantly from the original architect’s design drawings, by as much as 6” in places. 3D laser scanning enabled Hoffman to work with the architects and engineers to create highly accurate as-built CAD structural frame drawings. These “existing condition” CAD files were then given to the subcontractors to allow them to create more accurate 2D and 3D shop drawings and layouts, perform clash detection, and plan actual system layouts more efficiently than could have been done by attempting to manually measure for conflicts with the existing concrete structure.

Hoffman Builds: Industry-Leading Virtual Design and Construction

Hoffman has led the industry in the development of cutting-edge virtual design and construction tools. Hoffman is implementing Building Information Modeling and Virtual Design and Construction on a variety of projects to help teams coordinate and control projects down to the smallest detail.