The Flagship of the Seattle Public Library System and a True Civic Icon

Seattle Central Library

A building like this had never been built before. The structure conceived by the architects – the Office for Metropolitan Architecture in Rotterdam and Seattle’s LMN, in a joint venture – was a 12-story, glass-clad, asymmetrical building with multiple cantilevers, sloping surfaces, and dramatic geometric angles. The glass cladding was shown in a diamond pattern, and the architects’ desire was for a transparent building that floated with no apparent means of support.

The Seattle Central Library is the flagship of the Seattle Public Library system. Innovative in both form and function, the contemporary, glass and steel building is the third central library to occupy the city block between Fourth and Fifth Avenues.

The design objective, by Rem Koolhaas and Joshua Ramus, in partnership with LMN, was to create a building that honors books, and at same time, is very forward-looking to reflect major technological advances in the information business.

Challenge

How can a construction team use technology to realize extraordinarily ambitious design goals, including a skin system with thousands of glass panels in a multi-faceted steel web?

Solution

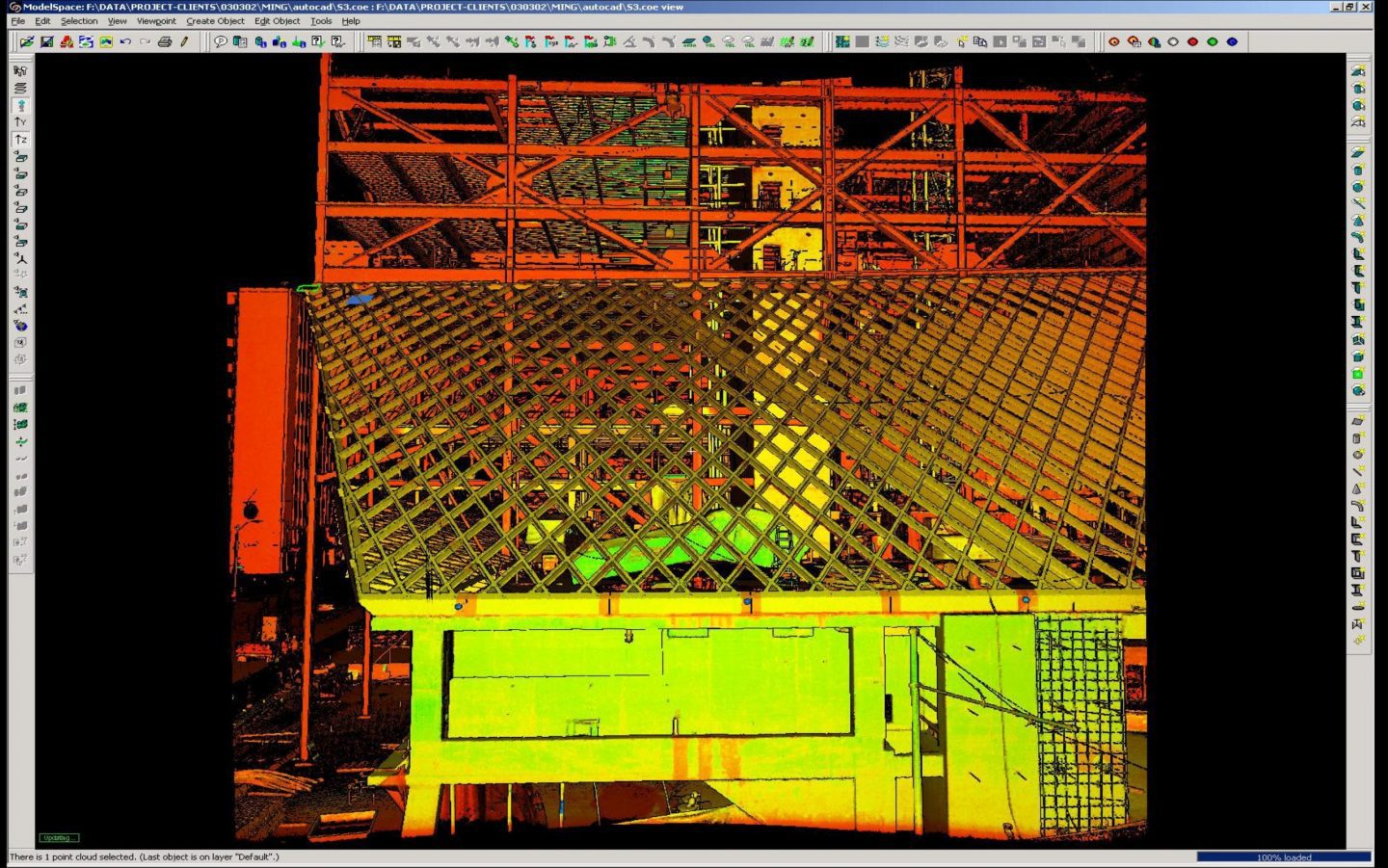

It was crucial to join together with the architects and engineers as true partners to bring OMA’s challenging design vision to life. BIM was used to model the library’s complex building skin system, which consists of thousands of glass panels over a steel web. Steel was digitally-scanned daily to create a 3D as-built model. Hoffman’s BIM team then steel erectors then used the scan to adjust the work to keep it perfectly aligned with the planned geometry.

-

2019 Best-Designed Building: Washington State — Architectural Digest

2019 The Best Architecture of the 21st Century (#4) — The Guardian

2005 Honor Award for Architecture — AIA National

2005 Honor Award — AIA NW & Pacific Region

2005 Library Award of Excellence — American Library Association

2005 Platinum Award — American Council of Engineering Companies

2004 Building of the Year — Time Magazine

2004 Platinum Building Team Project Award — Building Design & Construction

-

The Best-Designed Building in Every U.S. State

Architectural Digest — May 22, 2019

Today, much of this construction story is hidden behind the dramatic folds and planes of the Library’s glass exterior. Each day as many as 12,000 visitors pass through the library’s doors, many drawn as much by the building’s structure and architecture as they are the books.

Robust Constructability Through BIM

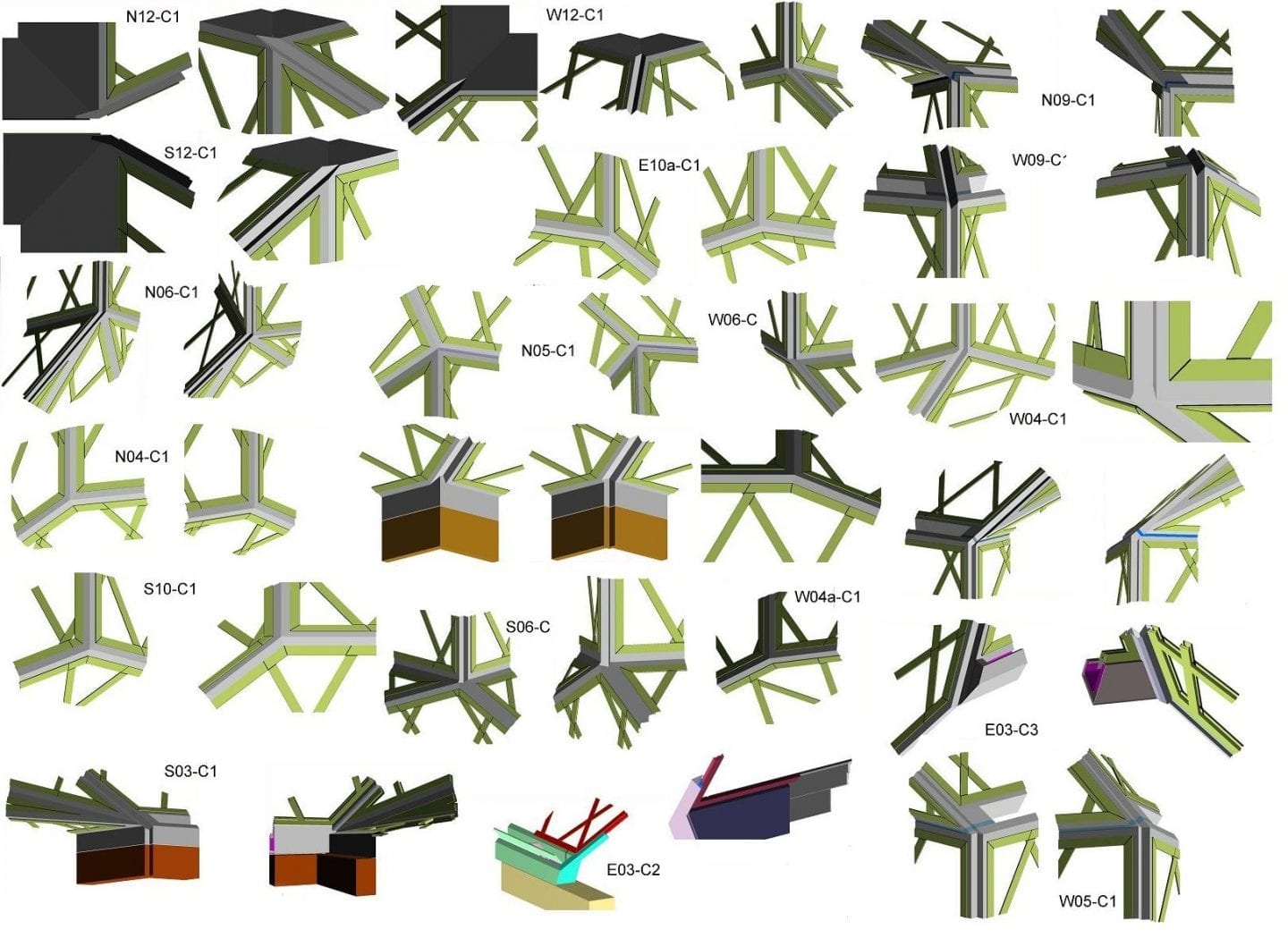

Looking at the planes and folds of the Library, the word “random” might come to mind. However, the fold transitions were anything but. At some folds, the architects wanted a gutter or “negative” fold to emphasize the edge of a face; in other places, a point was desired. No two folds were alike, due to the building’s geometry and asymmetry, and every time a fold line was shifted, even very slightly, it changed the geometry of the entire building face. Each fold decision also impacted the detailing, design, and construction of the various joins, including the steel connections.

Hoffman led a study to determine the optimum diamond size and shape, both for constructability and cost. Hoffman worked closely with OMA, LMN, MKA and Seele GmBh, the curtain wall design build subcontractor, to establish the optimum grid size and spacing for span, performance, fabrication, and aesthetics.

Creating a “Kit of Parts”

Once the entire building was modeled and steel shapes assigned, MKA and Hoffman assessed constructability for all corner steel conditions. Instead of detailing every one of the thousand or more joints, MKA developed a “kit of parts” with individual details applicable to several conditions.

Laser Scanning

The steel erection sequence was complicated, as the seismic steel grid panels had to support the building not only upon completion, but also during erection. This meant the panels had to be hung and bolted off before the structure could advance upwards. The panels also had to accommodate building movement as construction proceeded, yet still meet stringent construction tolerances. The process called for ongoing and extremely accurate surveying.

Hoffman turned to digital laser scanning, relatively commonplace today, but absolutely cutting edge at the time. Hoffman “shot” every panel erected with the digital laser scanner from at least three separate points, then examined the graphical reports produced for areas where the Xsteel model and the erected surface varied by more than ½ inch. After quickly pinpointing these locations, Hoffman performed field adjustments by either pushing or pulling the steel into place. As might be expected, pulling on one corner of steel can impact the location of the entire piece, so adjustments were complicated. Once the steel was within acceptable tolerances, it was permanently bolted.

Hoffman quickly adopted a routine of hanging steel in the morning, laser shooting it in the afternoon, analyzing the reports in the evening, then reporting the results to the ironworkers the next morning. Any panels adjusted were “reshot” to verify location and determine any corresponding ripple effect. Due to the tight schedule and small construction staging area, the sequence of hanging, shooting, analyzing, adjusting, and reshooting had to be stringently followed.